UNDERSTANDING THE PROCESS OF LED ENCAPSULATION

Why Encapsulate LEDs?

Think about a tiny lightbulb that isn’t covered. That’s very much the same as an unencapsulated LED. An LED’s sensitive chip is very vulnerable to harm from physical impact, moisture, water, heat and dust. Encapsulation solves this by enclosing the LED chip in a shield of protection. This barrier fulfills a number of vital purposes:

Chip protection: It keeps the delicate LED chip safe from environmental factors including dust, moisture, water, heat and dust maintaining its long-term performance.

Preserves optical qualities: The encapsulating substance ensures constant and appropriate light output by permitting light to flow through effectively while blocking damaging UV rays.

Improves heat dissipation: Encapsulation materials frequently possess high thermal conductivity, which helps with the LED chip’s heat dissipation—a critical process for preventing overheating and maintaining peak performance.

Provides structural reliability: The LED is given a defined shape and structure by the encapsulating material, which facilitates handling and assembly into a variety of lighting applications.

The Encapsulation Process:

A number of carefully regulated processes are involved in LED encapsulation, and each one is essential. This is an outline of the usual procedure:

1. Use of Encapsulating Material:

Applying Encapled Resin over the LED chip and wire bonding is the main step in the procedure. Encapled Resins have unique qualities such as moisture resistance, excellent light transmittance, and strong thermal conductivity.

2. Examining and Testing:

The LEDs go through comprehensive testing and inspection after the process of encapsulation is finished to make sure they fulfill the required standards. This entails testing the mechanical integrity, color consistency, light output, and electrical performance. To guarantee that only superior products make it onto the market, any LED that doesn’t live up to these strict requirements is either thrown out or modified.

Factors Influencing LED Encapsulation:

The quality of the finished product and the effectiveness of the LED encapsulation procedure depend on a number of factors:

Selection of Encapsulation Material: The performance and dependability of the LED are greatly impacted by the encapsulation material used. It is important to carefully analyze factors like moisture resistance, light transmission, thermal conductivity, and thermal expansion coefficient.

Process Control: To guarantee constant quality and avoid flaws, exact control over variables like temperature, pressure, and curing time is necessary.

Cleanliness: The performance and lifetime of an LED can be greatly impacted by even minute levels of pollutants. Thus, it is essential to keep the environment tidy and under control during the encapsulation process.

A Material Choice of Significance:

The choice of encapsulant material significantly impacts the performance and reliability of the LED. Key considerations include:

Transparency: To minimize internal losses and maximize the efficient transmission of light produced by the chip, the material must possess a high degree of transparency.

Thermal Conductivity: To effectively dissipate heat away from the chip, the material must have a high thermal conductivity.

Moisture Resistance: To stop corrosion and provide long-term dependability, the encapsulant must successfully stop moisture penetration.

Chemical Resistance: The material’s ability to endure severe chemicals and UV radiation over time assures its integrity.

Conclusion:

A seemingly straightforward but essential procedure called LED encapsulation is essential to turning small chips into dependable and effective light sources. It guarantees LED longevity, performance, and protection, making them a practical and sustainable option for a range of applications. Anticipate new developments in material science, innovative encapsulation methods, and technology integration in the future. Further reinforcing LEDs’ dominant role in creating a brighter future, these improvements, along with an emphasis on sustainability and environmental responsibility, promise even more efficient, dependable, and adaptable LEDs.Recent posts

Exhibitions 2025

LIGHT25

19th – 20th November 2025

London, UK

Booth: T38

Why is LED Encapsulation Technology Important?

LEDs are everywhere. They light up streets, homes, and even mobile phones. However, have you ever thought about how these minute parts are made?

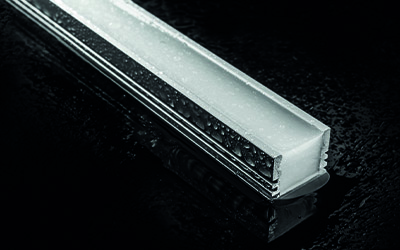

Resin Layering on LED Lights

Resin layering allows the encapsulation to be specifically customized which enhances the performance and durability of the luminaries.

A typical layering profile is as follows